TOUR THE BREWERY

We offer free tours of our production facility to give our guests an overview of the brewing processes, from concept to finished product. Each guided tour lasts approximately 10 minutes and includes a walkthrough of the brewhouse.

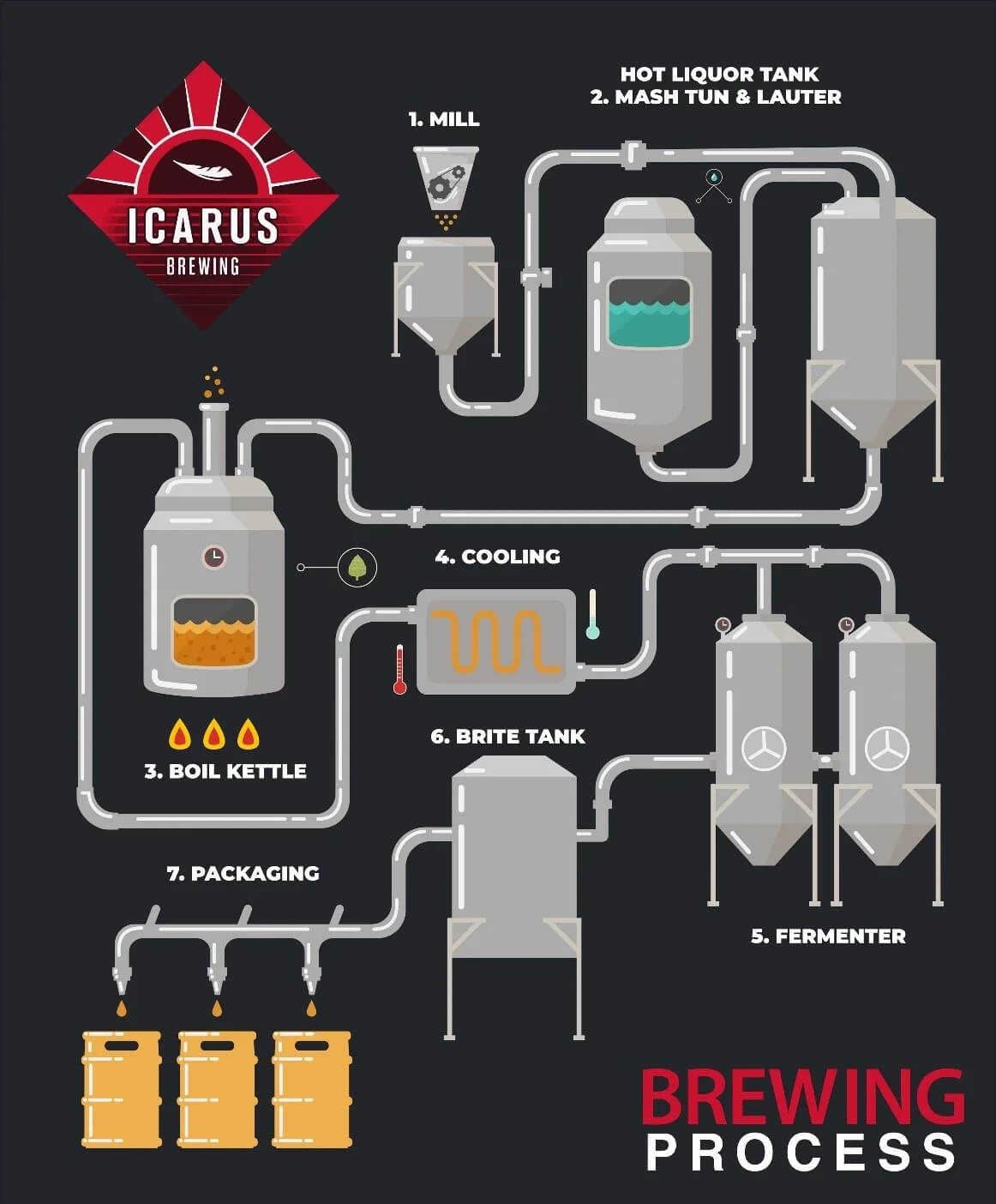

OUR BREWING PROCESS

We hope you enjoy your time here at Icarus Brewing!

Step 1

First we dump different types of grain from all over the world into the mill. The mill crushes the grain and creates what’s called “grist.” The grist gets pumped up the auger and dumped into our mash/lauter tun.

Step 2

Once the grist is in our mash/lauter tun, we fill it with hot liquor (treated water) from our hot liquor tank. This steeping process extracts sugars from the grist to be used in the fermentation process. The sugar enriched hot liquor is called “wort” which gets moved into our boil kettle, and the spent grist is sparged (rinsed) with hot liquor to gather any residual sugars and fill the boil kettle. The grist is removed from the mash/lauter tun and the spent grain is given to local farmers to use as animal feed.

Step 3

We boil off any contaminants in the boil kettle while adding bittering hops and other adjuncts for aroma and flavor. This process takes roughly an hour. The wort is then sent through our heat exchanger.

Step 4

The heat exchanging process allows us to quickly cool down our beer so we can pump it into our fermenters.

Step 5

We have multiple fermenter tanks, capable of holding 10, 20, 30, and 40bbl (barrels). Yeast is added to the fermenter, and it consumes the sugar in the wort, producing alcohol. This process can take 10-14 days. The wort can now be called beer. When fermentation is complete, the beer is sent to the brite tank.

Step 6

The beer in the brite tank goes through a carbonation process, and upon completion is ready for packaging.

Step 7

Our beer is canned and kegged, then off for distribution around the state!